How does the material in speaker diaphragms relate to sound?

Kevlar. Paper. Aluminum. Beryllium. Wood.

There is a dizzying array of materials available on the speaker market. What’s the best option? Is there one? Does it even matter?

You need to know, and so do your customers. With the home theater market projected to continue upward, it helps to have an understanding of what goes into the materials that make up speakers and speaker diaphragms so you can capitalize on this growing market.

How it Works

A Proficient speaker works by using a coil powered by an electromagnet to cause vibrations in a diaphragm. Good sound reproduction depends on a speaker diaphragm being able to respond quickly and accurately to the impulses coming from its coil. At the same time, speaker diaphragms need a minimum of warping, to ensure the sound stays accurate across the board. They also need to be stiff enough to not continue vibrating after the original sound impulse ends, but soft enough that the sound doesn’t “ping” off the diaphragm.

The ideal speaker diaphragm material would be as light as air and strong as steel. Unfortunately, in the real world, that material just doesn’t exist.

All Speaker Diaphragms are a Compromise

Perhaps the best material available on the market might be beryllium, which combines tremendous strength and incredible lightness. But it’s also toxic and way too expensive for common use. All diaphragm materials are a compromise between strength and lightness—at one extreme you have a metal like aluminum, which has strength but bad damping, allowing for ringing if it’s not properly treated. At the other, you have soft materials like silks.

Most diaphragms are “doped”, or treated with chemicals that affect the damping and strength of the diaphragm. Some are made of composites, layered between soft and hard materials like an audio sandwich. Others use different configurations to make a difference in sound—for example, slit patterns in the paper which are then laminated together.

So what are some of the most common soft and hard materials, and what effect do they have on the sound?

Soft Speaker Cones

No speaker cone can be entirely soft, because speakers are reliant on a certain amount of stiffness to allow for sound reproduction. Ideally, speaker movement is “pistonic”—the dome moves as one big piece, just like the piston on a car, without any sort of wobble or warping. Soft materials have a harder time with that.

But plastics tend to be on the softer side of speaker cones. Most plastic cones are in lower-end speakers, but it’s definitely possible to make a speaker with a plastic cone that provides good sound. If well-engineered, they usually excel at midrange frequencies.

Silk, other treated textiles, and synthetic films like PET are sometimes used in tweeters, though not usually in bigger speakers. These tweeters inherently have better damping than stiffer materials, and they don’t ring the way that the other common tweeter material (metal) can. Frequency response also tends to be smoother. They do break up through their frequency range more than firmer materials do, though.

Stiff Speaker Cones

Speaker cones are usually made of stiffer materials, as the tradeoffs in damping are usually balanced by the increased precision. There’s a wide variety of stiff materials that are used for speaker production.

Paper cones are paper in name only—they usually have a formidable amount of chemical formulation and doping applied, and construction matters a lot because of the amount of variation that’s possible. All paper cones aren’t the same. They have excellent characteristics across the board, but can be vulnerable to moisture, which changes the mass and damping of the cone.

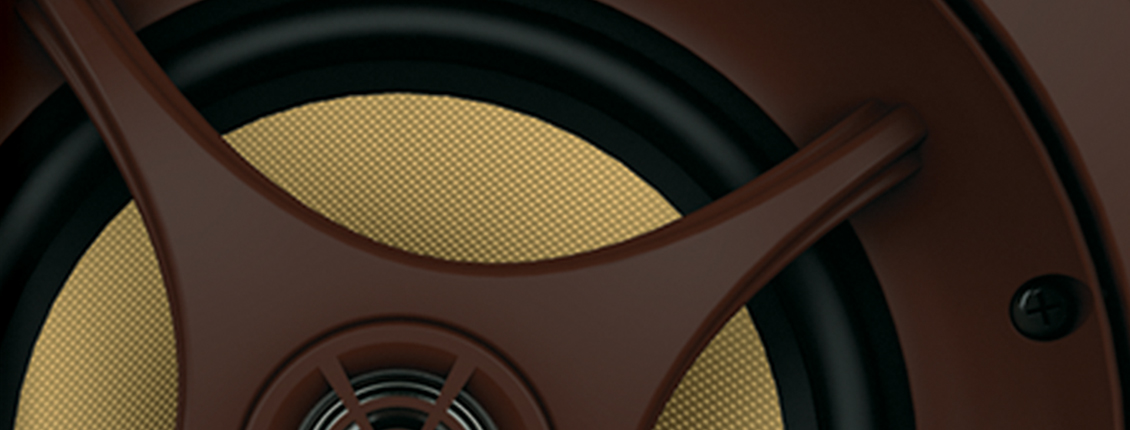

Proficient often uses Kevlar and other synthetic polymers, which are also good materials for speaker cones. They’re stiff, but retain enough flexibility to have good sound damping characteristics without the ringing or high-frequency ping that can be a problem with heavier metallic cones.

Metal cones are the stiffest of the possible materials, with aluminum and sometimes titanium being the most common. Metal is often used in tweeters. It’s precise and maintains its stiffness, but can have problems with ringing if not properly damped.

Proficient’s Signature series uses Kevlar for the speaker diaphragms of its midrange speakers and woofers. Kevlar has been used in speaker construction for decades—it’s one of the most tried and true materials. With high stiffness, it makes accurate sound reproduction easy. Aluminum, too, is a tried and true material, and the one Proficient uses for the tweeters in their Signature series.

Though stiffer materials can be prone to ringing at higher frequencies, Proficient’s sound engineers have worked to mitigate that tendency. All speaker materials are a compromise, and this Signature line hits a sweet spot that allows for accurate reproduction across a broad spectrum.

Why it Matters

So do the materials used in speaker diaphragms matter? They do, but good engineering, build quality and attention to detail can make almost any material sound good. That’s why Proficient’s Signature line stands out with its rock-solid performance. It’s a trusted brand for installers across the country, with excellent sound and a good price point. If you haven’t tried their speakers yet, take a look at the Signature line and see what sets them apart.

Check out Petra.com for our full range of speaker options from Proficient and see what makes them the right choice for you.